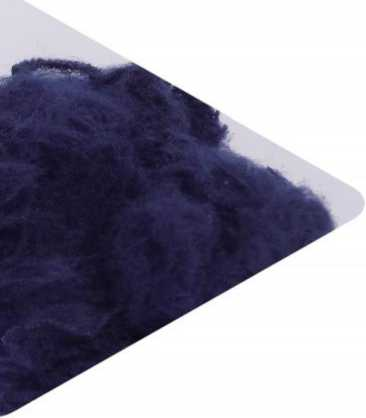

Alkali reduced polyester Dingdao Island Island fiber

1、 Basic Information

1. Name: Alkali Reduced Polyester Dingdao Island Island Fiber

2. Composition materials

-Marine material: Alkali soluble polyester (COPET), which has good alkali solubility and can be effectively dissolved in specific alkali treatment processes, thus achieving the special structural effect of sea island fibers.

-Island phase material: Polyethylene terephthalate (PET), 15/85, with relatively less island phase components, the fibers may be softer and finer; Fibers with higher proportions of islands (such as island ratios of 16, 64, 2D) are finer and softer, making them suitable for making products with higher tactile requirements, such as high-end garment leather; And larger fineness (such as<span style="font family:" font size: 14px; The fiber strength of 5D is relatively high and can be used in fields that require high strength, such as some components in automotive interiors.

6. Types: including short fibers and long fibers. Short fibers are short fibers cut into a certain length, with good fluffiness and spinnability, suitable for blending with other fibers, and used to manufacture various textiles; Long filaments are continuous fibers with high strength and uniformity, which can be directly used for weaving or processing into various functional fabrics.

7. Color: Available in white and color options, with color options customizable according to specific user needs. White fibers have good dyeing properties, making them convenient for subsequent processing into various colored products; Customized colored fibers can meet users' specific color requirements and provide more possibilities for product design.

2、 Purpose:

1. Automotive interior field

-Seat fabric: Alkali reduced polyester island fiber has good softness and wear resistance, providing a comfortable riding experience. Its delicate fiber structure can make the seat surface smoother, reduce friction with clothing, and have good anti fouling performance, making it easy to clean and maintain. In addition, the high strength and stability of fibers can ensure that the seat fabric is not easily deformed or damaged during long-term use, extending the service life of the seat.

-Interior decorations: such as door interior panels, dashboard decorations, etc. The customizable color and excellent appearance of this fiber can meet the diverse needs of automotive interior design, creating a high-end and comfortable interior environment. At the same time, the flame retardancy and low volatile organic compound (VOC) emissions of the fibers meet the safety and environmental requirements of automotive interior materials.

2. Clothing leather field

-Artificial leather: Artificial leather made from alkali reduced polyester island island fiber has a similar appearance and feel to natural leather, with high softness and good breathability. Its delicate fiber structure makes the surface of artificial leather smoother and more uniform, with good texture and glossiness. In addition, the fiber has strong wear resistance and chemical corrosion resistance, which can ensure that artificial leather is not easily damaged or faded in daily use, extending the service life of the product.

-Clothing fabric: In some high-end clothing, this fiber can be blended or interwoven with other fibers to create fabrics with special texture and performance. For example, blending with natural fibers can improve the moisture absorption and breathability of the fabric, while maintaining the high strength and wrinkle resistance of the fibers; Blended with functional fibers can endow fabrics with more functions, such as waterproofing, antibacterial, etc.

3. Wiping cloth field

-Precision instrument wiping cloth: Due to the high specific surface area and good moisture absorption of alkali reduced polyester fixed island fiber, it can quickly absorb and wipe various liquids and stains. Its delicate fiber structure will not scratch the surface of precision instruments, and it also has good wear resistance and anti-static performance, which can effectively prevent static electricity from adsorbing dust during wiping, ensuring the cleanliness and normal operation of precision instruments.

-Industrial wiping cloth: In industrial production, wiping cloth made of this fiber can be used to wipe off oil stains and dust on the surfaces of mechanical equipment, metal products, etc. Its high strength and chemical corrosion resistance can adapt to various harsh industrial environments, and it can still maintain good wiping effect after multiple uses.

Sales Manager: Mr. Yu, 18766152658 (WeChat ID: 18763957669)

Sales Manager: Mr. Yu, 18766152658 (WeChat ID: 18763957669)  Phone:0534-5056196

Phone:0534-5056196  Address: No. 191 Tiandingfeng Road, Linyi County, Dezhou City, Shandong Province

Address: No. 191 Tiandingfeng Road, Linyi County, Dezhou City, Shandong Province